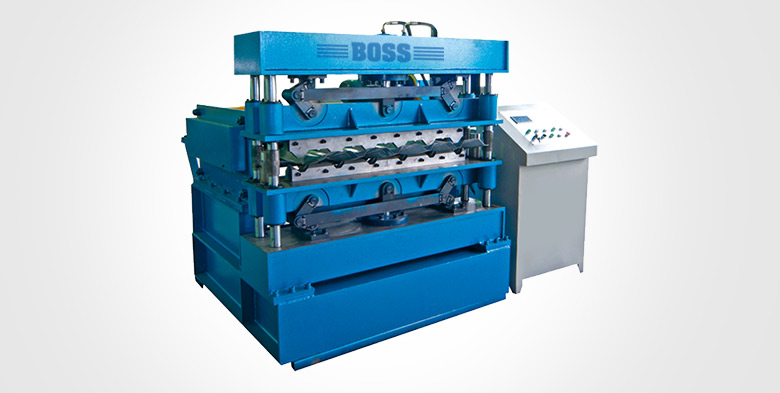

The main frame of Crimping machine is welded separately and the outside wall is connected by screw after being rotoblasted on the surface. Roller Material is high grade No.45 forged steel, with digital-controlled procession. Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product. The rollers are plated with hard chrome with thickness of 0.05mm on the surface after being machined by the exact machine tool. So that ensure long life of forming rollers. The suitable material thickness (C is the width of corrugated sheet produced by roll forming machine) is C×0.4~0.6 mm, Raw Materials will be Color Steel Sheet. The yield strength of raw material is 235-400Mpa. The Shaft diameter is 72mm, Quantity of feeding rollers is about 3 stations, Crimping length is min.25 mm and time is 10times/minute. Power voltage:415V/50Hz, 3 phase and main machine motor power: about 2.2kW (Depend on final design). The outside dimension size is 1600mm×1600mm×1750mm (length×width×height)

It adopts Post Curving and Stop to curve. The curving blade material is Cr12 with quenched treatment. It also adopts welded frame for good rigidity. The Curving frame has been heat treatment to avoid final product deformation.The power of Curving is provided by hydraulic station. The final product can be curve as per set length in PLC controller, and the length is automatically measured by encoder. When final product reaches the set length, machine will stop to curving the product automatically. Finish this action, machine will run again continuously.

It supplies the power for the Hydraulic Curving. All hydraulic accessories are all use Chinese famous brand products. The Hydraulic Motor Power is about 5.5kW

PLC Control System uses Mitsubishi PLC to control the all working actions. Production quantity and each piece length will be automatically measured. It is convenient to control the roll forming machine. Mitsubishi converter adjusts speed technology, realize the automatic production. Touch screen is input and canceled the working data. Friendly man-machine interface system can be set batches to the workpiece, length, quantity, etc. Encoder count, having function of count and measuring length.